For microbiologically demanding goods such as foodstuffs, pharmaceuticals or cosmetics, hygienic processing and packaging is vital to ensure that products maintain their quality from processing to consumer and meet stringent safety standards. Both processing and packing areas and the packaging materials themselves can be disinfected using a variety of methods, and UV irradiation is recognised as an environmentally-friendly, reliable and cost-effective tool. It is particularly effective for products that are sensitive to heat or chemical change.

Common areas in processing and packaging where UV disinfection is seen are:

- Surface disinfection lamps in processing areas and on equipment, for example conveyor belts, cutting and slicing blades, weighing platforms, bottling machines and mixing areas. UV disinfection is also seen as a useful tool for mitigating the risk of cross-contamination between low and high ‘care’ areas of processing plants.

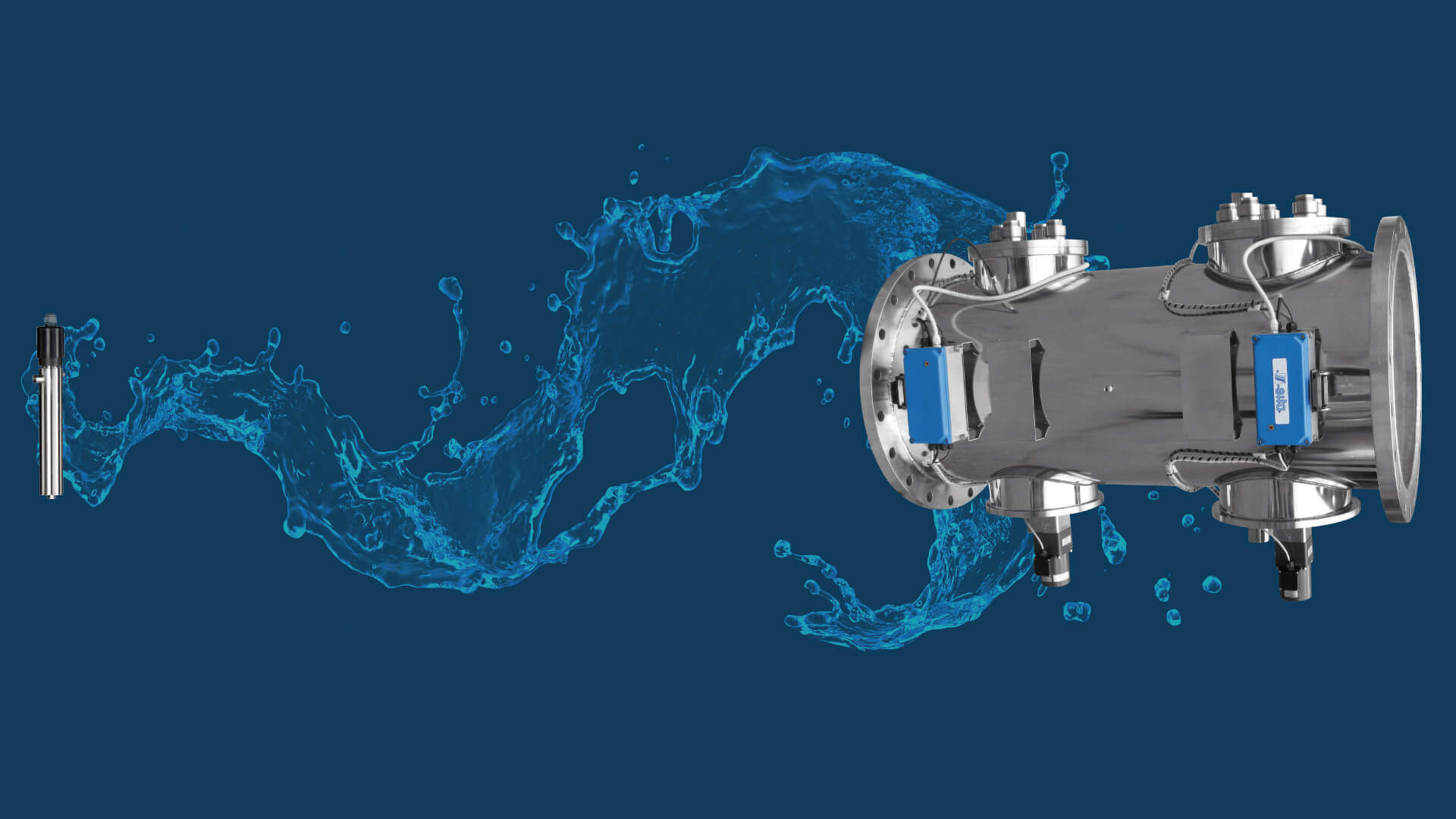

- Water disinfection systems to treat water used for washing meat, fruit, salad and vegetables prior to packing.

- Air disinfection systems for key areas in processing and packing areas to help ensure microbial load of the air is as low as possible. Air disinfection is of course a chemical-free process which makes it particularly suitable for

- Disinfection systems on the packing machinery itself, targeting boxes, trays, cartons, pots, sealing foils, lids, bags, caps and tops for bottles and jars, bottle necks themselves and so many more.