UV technology is used in pharmaceutical research and manufacturing sites for the production of ultrapure process water, disinfecting air or surfaces and for ensuring lab tools and personal safety equipment meet stringent standards.

Ultrapure Water

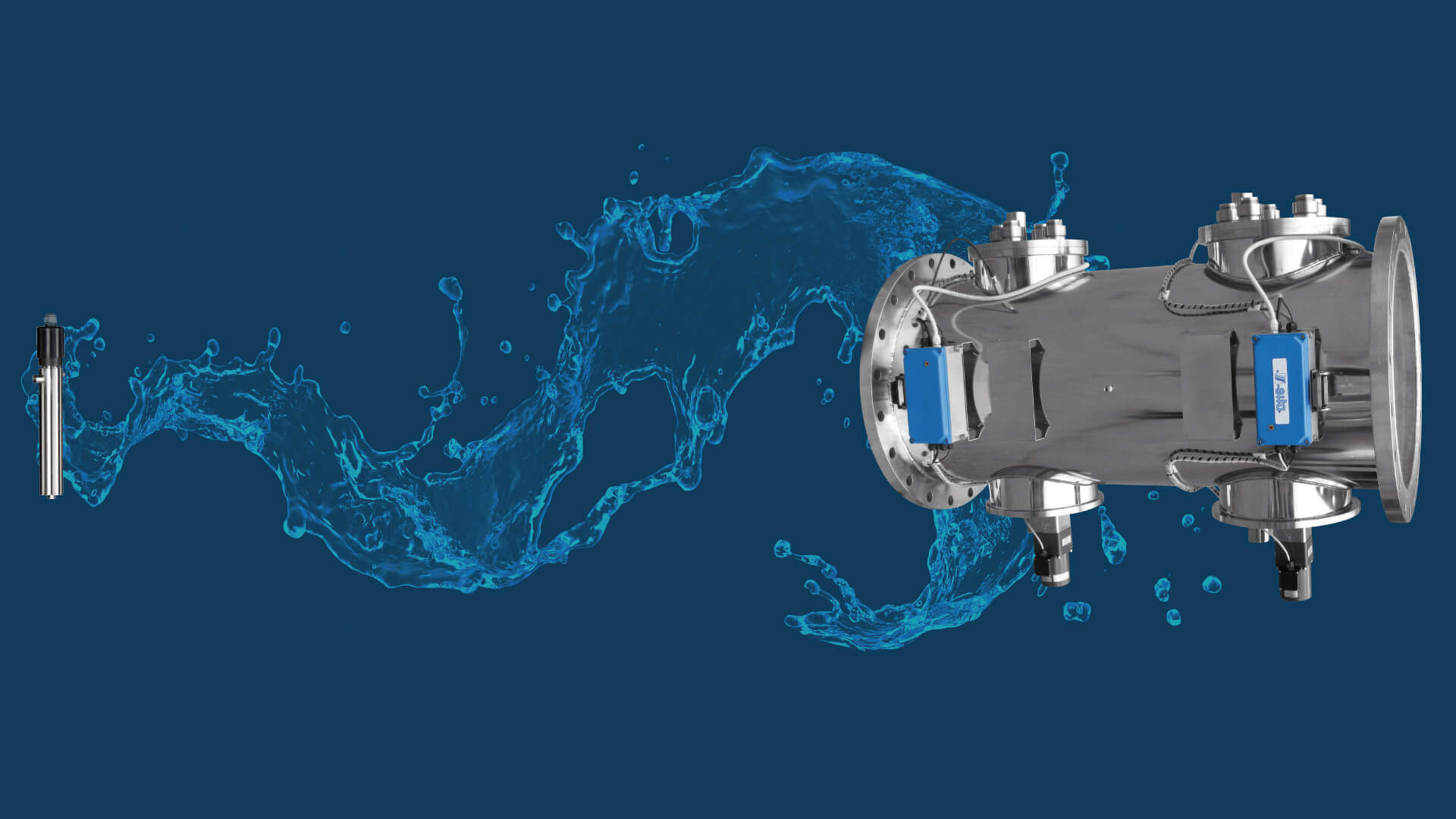

Ultrapure water is treated through multiple steps to meet the quality standards for different users. UV disinfection systems are used to render microbes and pathogens in the water harmless, and to remove ozone and chlorine from process water, particularly if it has been disinfected using chemical methods previously, which can leave high levels of ozone.

Disinfection of the working environment

Laboratories employ the use of ceiling-mounted UV systems to disinfect air as it is circulated throughout the facility and banks of UV lamps to disinfect rooms and storage areas.

Cleaning equipment and protective equipment

After conventional chemical cleaning laboratory equipment is sent through a UV disinfection ‘tunnel’ or stored in a UV light box overnight. Personal protective equipment can be treated with handheld germicidal lamps to ensure no contaminants remain

Treating laboratory discharge water

UV water disinfection systems are used to treat effluent water from laboratories or pharmaceutical manufacturing facilities, to ensure any potentially toxic by-products they have been added in during testing and chemical processes are render harmless.